Steam turbines that condensate play an essential role in the production of powerful power generation. They are frequently employed in various industries, such as Industrial Captive Power Plants, Oil & Gas Plants, Utility Power Plants, and Geothermal Power Plants. Their capacity to extract the most energy from steam can help lower operational costs and boost efficiency of energy.

Condensing steam turbines: what are they?

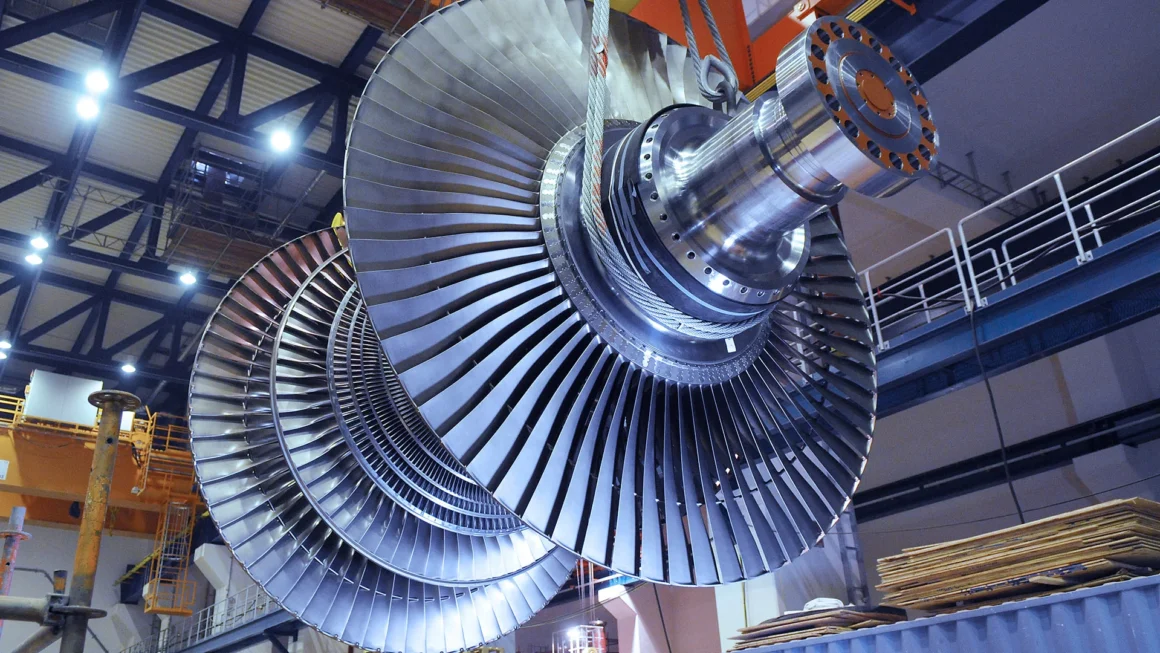

Condensing turbines are engineered to maximize energy efficiency through the conversion of steam to water after it is passed through turbine blades. This is done in a condenser where exhaust steam is then cooled and then condensed in conditions of vacuum.

As an essential element in the Rankine cycle Steam turbines boost the efficiency of thermal energy and decrease the consumption of fuel. Their capacity to manage variable load makes them ideal to baseload and peak load operations.

How Do They Conserve Energy?

Condensing steam turbines improve efficiency of energy by increasing steam expansion, and creating a vacuum that improves the conversion of energy. This reduces the use of fuel and maximizes thermal efficiency and ensures efficient energy generation.

- Maximized Energy: Extraction condensing steam into water it creates a vacuum which enhances the pressure drop across the blades of the steam turbine and improves efficiency in energy conversion.

- Lower fuel consumption: Efficiency of steam use in condensing turbines means an increase in energy derived by each unit prior to it is condensed into water. This process is highly efficient and minimizes the need for further steam generation, thus reducing energy consumption. By optimizing the cycle of thermal energy, businesses are able to make substantial savings on fuel expenditures.

- Lower heat rejection: Condensing in steam turbines helps to reduce the loss of heat by turning exhausted steam to water in lower temperatures. This improves the effectiveness of the Rankine cycle by reducing amount of heat that is wasted to the atmosphere.

- Reduced heat rejection: not only enhances the thermal performance of the system, but can also lower cooling demands and can result in cost savings for cooling infrastructures and energy consumption.

- Improved Load Handling: Condensing Steam turbines are extremely adaptable to the demands of different loads, which makes them suitable for applications where power needs vary. Their capacity to effectively manage different loads guarantees steady performance and maintains their efficiency even under periods of partial load.

Techniques for Cutting Costs with Condensing Steam Turbines

Condensing steam turbines can reduce expenses by enhancing the efficiency of energy, reducing energy consumption, and enhancing thermal efficiency. These elements help to reduce operating costs while increasing output of power.

- Optimized plant operations: Streamlined procedures result in less energy consumption.

- Longer Operating Life: The latest design and materials help reduce damage and wear, thus reducing maintenance costs.

- Flexible Solutions for Scalable Operations: Ideal for small-scale and larger operations, they offer flexibility and efficiency without sacrificing.

Condensing steam turbines are a great option for businesses looking to maximize their energy use and decrease costs. Their capacity to increase efficiency, help sustain power solutions and minimize environmental impact make them a crucial component of the modern power generation system.

For companies looking for energy efficiency that is cost-effective and environmentally friendly investing in cutting-edge steam turbine technology can bring substantial operational benefits. Working with industry leaders such as Triveni Turbines can further enhance efficiency sustainable, long-term sustainability, and cost savings.